Description

To maximize performance, API pressure seal gate valve is not designed for regulating fluid flow. Instead, this kind of API valve is best used for cutting through sticky and dense petroleum liquids, permitting and preventing high fluid flow but with negligible friction loss. Constant flow changes may take a toll on this high pressure gate valve, causing early seat wear and eventual valve leaks.

Application

Pressure seal gate valves are widely applied in such pipelines in the fields of tap water, sewage, construction, petroleum, chemical, food, medicine, textile, electric power, shipbuilding, metallurgy, energy system, etc.

Features of Pressure Seal Gate Valve

1. Weld end.

2. Small flowing resistance.

3. Very low frequency of water hammer phenomenon.

4. Low opening torque.

5. High corrosion resistance.

6. 18 months’ free maintenance.

Attention and Maintenance

1. When choosing pressure seal gate valves, customers should pay more attention to the working pressure and temperature, sealing performance, diameter, structure, connection size and medium involved.

2. Before installing this welded gate valve, please check valve body, sealing surface and other parts to avoid any dirt attachment.

3. The installing position, height and the direction of entrance and exit should be complied with the design specifications.

4. Bolts at any connection joint should be fastened.

5. Hand wheel, handle, and transmission structure cannot be lifted up and down.

6. If by-pass valve is combined with pressure seal gate valves, the by-pass valve should be opened first to balance the entrance and exit’s pressure.

7. If gate valves are used frequently, please lubricate them at least once per month. And they should be maintained regularly.

Payment, Package and Transportation

We accept such payments as T/T, D/P, D/A, or L/C. Our API valves will be packed in standard wooden boxes and delivered by railway, sea, or airplane.

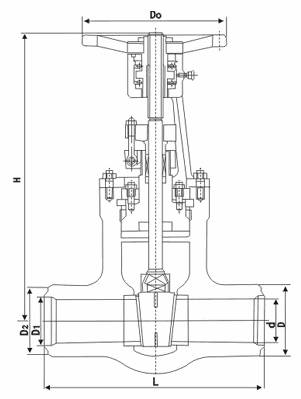

Structure of Pressure Seal Gate Valve