Description

Double block and bleed valves, also named DBB valves, are a space-saving dual isolation solution that reduces the need for costly multi-valve systems. By combining all block and bleed components into a single unit, KERUI DBB flange and welded ball valve minimizes the risk of leak paths to atmosphere while providing significant weight savings.

Advantages

1. DBB valves are integrally forged. They are compact in structure and light in weight, thus reducing installation and maintenance requirements.

2. Double block and bleed valves are commonly used throughout the oil and gas extraction industry, especially on floating platforms and storage vessels where space is a primary concern.

3. KERUI has been awarded by ISO9001:2008 international system certification, API 6D certification, CE certification, etc.

4. Sealing materials can be chosen based on media to increase sealing performance and wear resistance, reducing cost.

5. DBB valves can be custom engineered to meet various lengths, heights, and connection sizes.

6. Our double block and bleed valves are guaranteed within 18 months and enjoy lifelong technical service.

Features of DBB Valve

1. Compact design

2. Uninterrupted flow for negligible pressure drop

3. Reduced leakage points

4. Space, weight, and cost savings versus multi-valve systems

5. Reduced installation and maintenance requirements

6. Designed and engineered on a case-by-case basis

7. Compact profile for reduced risk of vibration damage

8. Optional features include probes, check valves, seat wipers, and injection quills

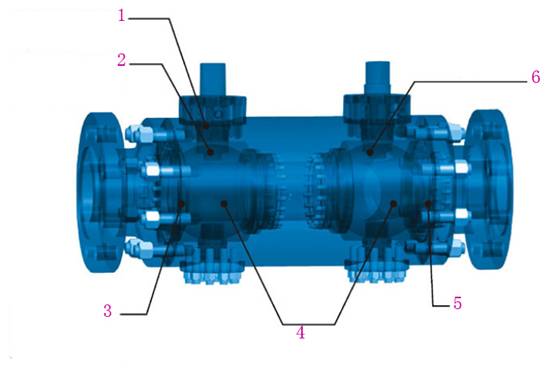

Components

DBB valves are mainly composed of valve body, bonnet, ball, valve stem, valve seat, sealing materials, etc.

Specifications

1. Double block and bleed ball valve bore, 4-24″ 100-600 mm

2. Double block and bleed ball valve pressure, 150LB~2500LB, 1.6Mpa~32Mpa

3. Full Port Design

4. Bolted Bonnet Split Body

5. Three Pieces Body

6. Trunnion Mounted Ball Type

7. Blow Out Proof Stem

8. Fire Safe Construction

9. Anti Statics Device

10. ISO 5211 Mounting Pad

Standards and Tests

1. Design Standard: API 6D

2. Face to Face: ASME B16.10

3. End Flanges: ASME B16.5

4. Inspection and Test: API 598

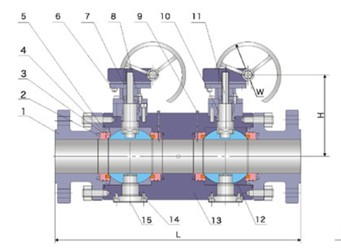

Structure of DBB Valve

|

No.

|

Part Name

|

ASTM Material

|

|

Carbon Steel

|

Alloy Steel

|

Stainless Steel

|

|

1

|

Bonnet

|

ASME A105

|

A352-LCB

|

A217+WCB

|

A351-CF8

|

A351-CF8M

|

|

2

|

Spring

|

INCLONEL750

|

A313-304

|

A313-316

|

A313-316

|

A313-316

|

|

3

|

Seat O Ring

|

Viton

|

Viton

|

Viton

|

Viton

|

Viton

|

|

4

|

Seat

|

ASME A105+ENP

|

A350-LF2 +ENP

|

A182+F316

|

A182-F304

|

A182-F316

|

|

5

|

Seat Ring

|

PTFE

|

PTFE

|

R.PTFE

|

Glass Filled PTFE

|

|

6

|

Stud

|

A193-B7

|

A320-L7

|

A193-B7

|

A193-B8

|

A193-B8

|

|

7

|

Connection Plate

|

ASTM A105

|

A352-LCB

|

A217-WC6

|

A351-CF8

|

A351-CF8

|

|

8

|

Packing Case

|

F4

|

|

9

|

Grease Injection Valve

|

SS

|

|

10

|

Stem O Ring

|

Viton

|

Viton

|

Viton

|

Viton

|

Viton

|

|

11

|

Stem

|

A182 F6a

|

A276-304

|

A276-316

|

A276-304

|

A276-316

|

|

12

|

Ball

|

ASTM A105+ENP

|

A182-F304

|

A182-F316

|

A182-F304

|

A182-F316

|

|

13

|

Body

|

ASTM A105

|

A352-LCB

|

A217-WCB

|

A351-CFB

|

A351-CF8M

|

|

14

|

Trunnion

|

A276-304

|

A276-316

|

A276-304

|

A276-316

|

|

15

|

Lower Cover

|

ASTMA105

|

A352-LCB

|

A217-WCB

|

A351-CFB

|

A351-CF8M

|

1. Double sealing o-ring: To prevent the leakage as the stem.

2. Blow-out proof stem: It is internally inserted the body and function as the up-sealing seat.

3. Ball valves are equipped with preloaded spring floating seat ring to ensure sealing performance even in low pressure.

4. Adopting double ball valve is to reduce the leakage in the stem and to achieve quick-safely bleeding.

5. Ball valves are equipped with preloaded spring floating seat ring to ensure sealing performance even in low pressure.

6. Blow-out proof stem: It is internally inserted the body and function as the up-sealing seat.