Description

DIN stainless steel welded globe valves (shut off valves) are used for regulating flow in a pipeline. This weld end globe valve consists of a movable disk-type element and a stationary ring seat in a generally spherical body. This DIN valve is widely used in such applications requiring throttling and frequent operation.

Application of Weld End Globe Valve

DIN stainless steel welded globe valves are utilized as regulation and cut-off device in such pipelines as tap water, sewage, construction, petroleum, metallurgy, energy system, chemical products, foodstuff, medicine, textile, electricity, ship, etc.

Advantages

1. Compared with similar brands, our DIN stainless steel weld end globe valves have advantages of good sealing performance, small friction between sealing faces and long service life.

2. Weld end globe valves need small torque to open.

3. Valve body is precisely cast.

4. Valve disc is processed by CNC technology.

Features

1. Featuring simple structure, DIN stainless steel weld end globe valves are easy to manufacture and maintain.

2. When starting or stopping shut off valves, the disc stroke is short. Therefore, its height is a bit lower than that of gate valves, but the structure length is longer.

4. Medium passway of this weld end globe valve is quite zigzag, so the hydraulic resistance is large, leading to big power consumption.

5. When in use, the flow direction of medium in globe valves is unidirectional and its flow direction can not be changed.

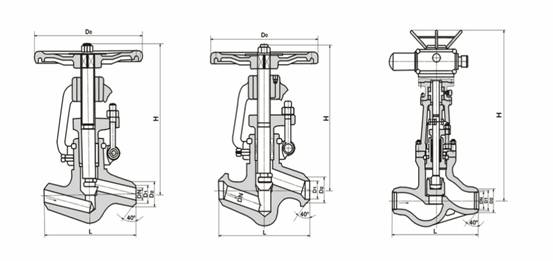

Structure of DIN Stainless Steel Weld End Globe Valve

Main Parts and Materials of Shut Off Valve

|

NO.

|

Part Name

|

Material

|

|

GS-C25

|

1.4308

|

1.4408

|

1.4306

|

1.4435

|

|

1

|

Body

|

GS-C25

|

G-X6CrNi18 9

|

G-X6CrNiMo18 10

|

G-X2CeNi18 9

|

G-X2CrNiMo17 12 2

|

|

2

|

Disc

|

1.4006 X10Cr13

|

1.4301 X5CrNi18 10

|

1.4401 X3CrNiMo17 13 2

|

1.4306 X2CrNi19 11

|

1.4435 X2CrNiMo17 12 2

|

|

3

|

Pin

|

1.4001 X7Cr13

|

1.4001 X7Cr13

|

1.4301 X5CrNi18 10

|

1.4301 X5CrNi18 10

|

|

4

|

Bellow assemble

|

1.4878 X12CrNiTi189

|

1.4401 X3CrNiMo17 13 2

|

1.4306 X2CrNi19 11

|

1.4435 X2CrNiMo17 12 2

|

|

5

|

Stem

|

1.4006 X10Cr13

|

|

1.4401 X3CrNiMo17 13 2

|

1.4401 X3CrNiMo17 13 2

|

1.4435 X2CrNiMo17 12 2

|