Description

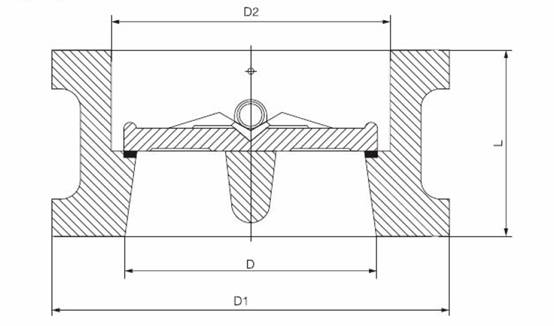

DIN stainless steel dual plate wafer check valve is mainly composed of valve body, disc and spring. It is installed on one-way flow pipelines and used to prevent backflow and leakage of medium as well as reversal of pump and driving motor. It can also be installed in auxiliary pipeline system to balance system pressure.

Application of Flanged Check Valve

DIN stainless steel dual plate wafer check valve can be installed in horizontal or vertical section of pipe. This type of dual plate check valve is widely applied in tap water, sewage, construction, petroleum, chemical, food, medicine, textile, electric power, shipbuilding, metallurgy, and other pipeline systems.

Advantages of Flanged Check Valve

1. Disc of DIN stainless steel dual plate wafer check valve is with high strength and stiffness. CNC processing technology is adopted to produce disc.

2. Two times shot blasting processing of valve surface make the valve look fine and smooth.

3. Disc restrainer is designed to prevent that the open position of disc is too high to be shut down.

4. Small friction between sealing surfaces ensures low wear rate of weld end check valve.

5. The disc sealing surface can be customized.

6. All our flanged check valves have 18 months warranty.

Working Process of Flanged Check Valve

DIN stainless steel dual plate wafer check valve works automatically. It opens and closes depending on force from media flowing. This dual plate check valve allows medium to flow through it in only one direction, and prevents reverse direction flow. Disc will open under the pressure of forward flow fluid. When fluid flows in reverse direction, the disc will be closed by fluid pressure and dead weight so as to cut off the flow.

Maintenance

1. For flanged check valves that are not to install temporarily, they should be stored in dry and ventilated room, side flange of the flanged valve must be sealed.

2. The check valve for long-term storage should be checked regularly. The surface of the valve must be clear of dirt and coated with anti-rust oil.

3. The following conditions of check valve should be inspected regularly after installation:

1) Wear pattern of sealing surface and rotary rocker

2) Dirt accumulation between the inner chamber of the valve body and sealing surface

KERUI products, such as ball valves, gate valves, globe valves, dual plate check valves, stainless steel valves and strainers, have reached the standard of US DIN, Germany DIN, Russia GOST, Japan JIS, ISO9001 and CE. Our flanged check valves are applied in various pipeline systems, such as tap water, sewage, construction, petroleum, chemical, food, medicine, textile, electric power, shipbuilding, metallurgy, energy, etc. Our products occupy a large market at Brazil, Argentina, Mexico, Canada, Russia, Kazakhstan, Indonesia, South Korea, Japan and other foreign countries.