Introduction

Weld end check valve, also known as butt welded check valve or non return valve, is an automatic valve that is installed on one-way flow pipelines. It is mainly made up of valve body, disc, bonnet and gasket. This type of weld end valve is used to prevent reverse flow and leakage of medium, such as fluid, gas, etc. This type of pipe valve is also applied to stop reversal of pump and driving motor. Our valves have passed API6D and CE certification.

Application

Butt welded check valve can be widely applied in tap water, sewage, construction, petroleum, chemical, food, medicine, textile, electric power, shipbuilding, metallurgy, and other pipeline systems.

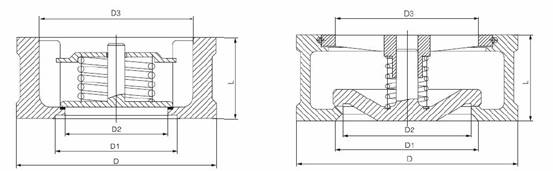

Structure Map

Advantages

1. Butt welded check valve (non return valve) features small closing torsion and excellent sealing performance.

2. CNC processing technology is adopted to produce disc.

3. Disc is with high strength and stiffness.

4. Disc restrainer is designed to prevent that the open position of disc is too high to be shut down.

5. High intensity and flexibility of rocker are beneficial to close disc.

6. Small friction between sealing surfaces ensures low wear rate of butt welded check valve.

7. The disc sealing surface can be customized. Customer can choose sealing material according to media in order to increase sealing property and wear resistance according to requirement.

8. Two times shot blasting processing of valve surface make the valve look fine and smooth.

9. All our weld end valves have 18 months warranty.

Features

1. Butt welded check valve (non return valve) opens and closes automatically depending on force from media flowing.

2. It allows medium to flow through it in only one direction, and prevents reverse direction flow.

3. Disc will open under the pressure of forward flow fluid.

4. When fluid flows in reverse direction, the disc will be closed by fluid pressure and dead weight so as to cut off the flow.

Classification of Butt Welded Check Valves (Non Return Valve)

1. According to structure, weld end valves can be classified into

1) Lift type (including vertical type and horizontal type) valve

2) Swing type (with single plate, dual plates and multiple plates) valve

3) Butterfly type (straight through) valve

2. According to connection type, butt welded check valves can be divided into

1) Threaded connection valve

2) Flanged connection valve

3) Welded connection valve

4) Wafer connection valve

Payment, Package & Transportation

1. Butt welded check valves can be paid by T/T, D/P, D/A, L/C, and so on.

2. Standard exporting wooden cases are employed for packaging.

3. Items are transported by air, sea or railway.

Lanteky Valve Industry is a professional manufacturer and supplier of weld end valves, such as ball valves, gate valves, globe valves, check valves (non return valves) and strainers in China. With high technology, great production capacity and strong innovation ability, we provide high quality and guaranteed weld end check valves. Our products occupy a large global market. For more information, please enter our website or contact us directly.